How sugar beet vs sugar cane differ in terms of processing methods and production efficiency

The Relevance of Sugar Beet Vs Sugar Cane: a Closer Look at Their Manufacturing Processes and Applications

The significance of sugar beet and sugar cane prolongs past their function as resources of sucrose. Each plant includes unique producing procedures that influence their applications across various sectors. While sugar beet sustains not simply food production yet also biofuels and fertilizers, sugar cane primarily serves the food field with valuable results. Comprehending these distinctions discloses exactly how each crop forms agricultural economic situations and sector methods globally, triggering further exploration into their one-of-a-kind payments.

Review of Sugar Beet and Sugar Cane

Sugar beet and sugar cane are 2 main resources of sucrose, each with unique characteristics and cultivation approaches. Sugar beet, an origin veggie, thrives in warm climates - Sugar beet vs sugar cane. It is cultivated primarily in the Northern Hemisphere and calls for well-drained dirt. The plant typically grows to an elevation of about 18 inches, with a white, fleshy origin including concerning 15-20% sucrose. In comparison, sugar cane is a tropical turf that flourishes in warm, damp problems. It can reach elevations of up to 12 feet and is composed of tall, jointed stems that store sucrose concentrations ranging from 10-15%. The cultivation of sugar cane is labor-intensive and often involves hand-operated harvesting. Both crops work as crucial farming assets, giving resources for sugar manufacturing and numerous byproducts. Their cultivation methods substantially affect neighborhood economic climates and worldwide sugar markets, making them important to the farming landscape

Harvesting Strategies for Sugar Beet and Sugar Cane

Collecting strategies for sugar beet and sugar cane vary noticeably as a result of the one-of-a-kind attributes of each plant. Sugar beet harvesting usually employs customized machinery referred to as beet harvesters, which efficiently root out the beets from the soil while reducing damage. These machines utilize a collection of blades to reduce the tops and lift the origins, making sure that the beets continue to be intact for processing.In comparison, sugar cane harvesting typically entails two primary techniques: manual cutting and mechanical harvesting. Hand-operated harvesting, still common in some areas, requires employees to reduce the cane stalks by hand using machetes. This method permits for discerning harvesting yet is labor-intensive. Mechanical harvesters have obtained popularity, utilizing revolving blades to reduce and gather the stalks rapidly. Both techniques aim to optimize yield and top quality, with mechanical harvesting significantly taken on to satisfy climbing production demands efficiently.

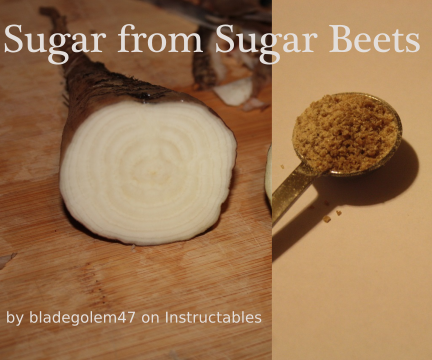

Handling Approaches for Sugar Beet

After being gathered, sugar beets undergo a collection of handling actions to remove sucrose properly. The initial step entails washing the beets to eliminate dirt and impurities. Next off, the beets are sliced right into slim strips referred to as cossettes, which raises the surface area for extraction. These cossettes are after that based on warm water extraction in a diffusion procedure, enabling sucrose to dissolve right into the water.Following extraction, the juice consists of pollutants and is made clear using lime and warm to precipitate solids. The made clear juice is after that focused through dissipation, getting rid of excess water and increasing sugar focus. To crystallize the sucrose, the concentrated juice undergoes further dissipation and cooling, creating sugar crystals. These crystals are divided from the remaining syrup via centrifugation, dried out, and packaged for distribution. This method guarantees a high return of sucrose while maintaining the top quality of the end product.

Handling Methods for Sugar Cane

Handling sugar cane involves a series pop over to these guys of steps developed to extract sucrose successfully. The process starts with harvesting, where fully grown sugar cane is cut and delivered to processing centers. When at the mill, the cane undergoes cleaning to eliminate contaminations. The following action is squashing, where mechanical rollers essence juice from the coarse stalks.This juice is then clarified utilizing warmth and lime to eliminate suspended solids and pollutants. Complying with clarification, the juice is evaporated to concentrate the sugar material, resulting in a thick syrup. The syrup undergoes condensation, where sugar crystals form as the syrup cools down. These crystals are divided from the remaining molasses with centrifugation.Finally, the sugar is dried out and packaged for circulation. This detailed processing technique assurances that sugar cane generates a high-quality product, suitable for various cooking and industrial applications, while maximizing the removal of sucrose from the raw material.

Nutritional Differences In Between Sugar Beet and Sugar Cane

The contrast in between sugar beet and sugar cane extends past their handling methods to incorporate significant nutritional distinctions. Sugar beet consists of not just sucrose however additionally a range of vitamins and minerals, including vitamin C, potassium, and magnesium. These nutrients add to its possible health and wellness benefits, such as supporting immune function and keeping electrolyte balance. On the other hand, sugar cane generally supplies sucrose with marginal degrees of essential nutrients.Additionally, sugar beet has a higher fiber content, which can aid in digestion and promote satiation. The presence of antioxidants in sugar beet might likewise offer protective impacts against oxidative stress, a factor linked to different chronic diseases. While both sources are largely used for sugar manufacturing, the nutritional accounts suggest that sugar beet might provide added health and wellness benefits compared to sugar cane. This difference is essential for consumers looking for even more than simply sweeteners in their diets.

Applications of Sugar Beet in Numerous Industries

A range of sectors leverage sugar basics beet for its versatile applications beyond sugar production. In the food sector, sugar beet offers as a crucial ingredient in producing numerous processed foods, consisting of sugary foods and baked items, as a result of its natural sweetness. In addition, the pulp derived from sugar beet is used as animal feed, offering a nutrient-rich source for livestock.In the biofuel field, sugar beet is progressively identified for its potential in creating bioethanol, adding to renewable power options. The agricultural field take advantage of sugar beet's by-products, which can be used as organic plant foods, view it enhancing dirt health and fertility.Furthermore, sugar beet removes are used in drugs and cosmetics, where they operate as all-natural sweeteners and humectants. These varied applications highlight sugar beet's role as a useful source in boosting sustainability and technology across several sectors, strengthening its importance in modern-day manufacturing practices.

Applications of Sugar Cane in Various Industries

Regularly Asked Questions

What Ecological Effects Are Related To Sugar Beet and Sugar Cane Production?

The environmental impacts of sugar beet and sugar cane production consist of soil deterioration, water use, pesticide application, and environment disruption. These variables add to ecological inequalities, raising worries regarding sustainability in farming practices connected with both crops.

Just How Do Sugar Beet and Sugar Cane Contrast in Terms of Economic Stability?

The economic stability of sugar beet and sugar cane varies based on factors like geographic place, manufacturing costs, and market need - Sugar beet vs sugar cane. Both plants offer distinct benefits, affecting farmers' choices concerning cultivation and investment in different areas

What Are the Main Regions for Sugar Beet and Sugar Cane Farming?

How Does Climate Influence the Growth of Sugar Beet and Sugar Cane?

Environment greatly affects the growth of sugar beet and sugar cane. Sugar beets prosper in cooler temperatures, while sugar cane needs cozy, tropical conditions. Sugar beet vs sugar cane. Both plants depend on adequate rainfall and sunlight for excellent development and return

Exist Any Kind Of Substantial Health And Wellness Concerns Related to Consuming Sugar From These Sources?

Health and wellness worries pertaining to sugar usage consist of excessive weight, diabetes, and heart condition. Both sugar beet and sugar cane-derived sugars can add to these concerns, specifically when eaten in too much amounts, no matter their resource.